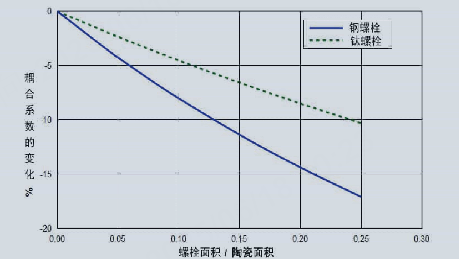

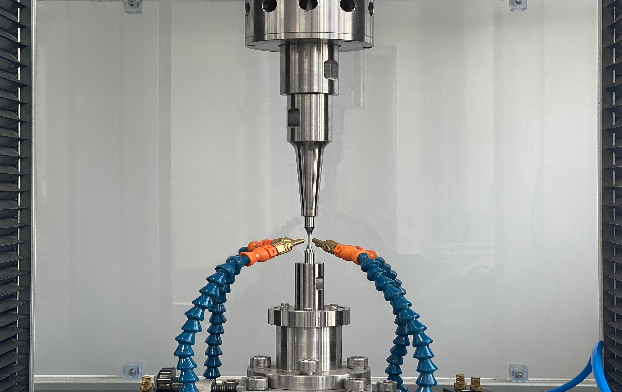

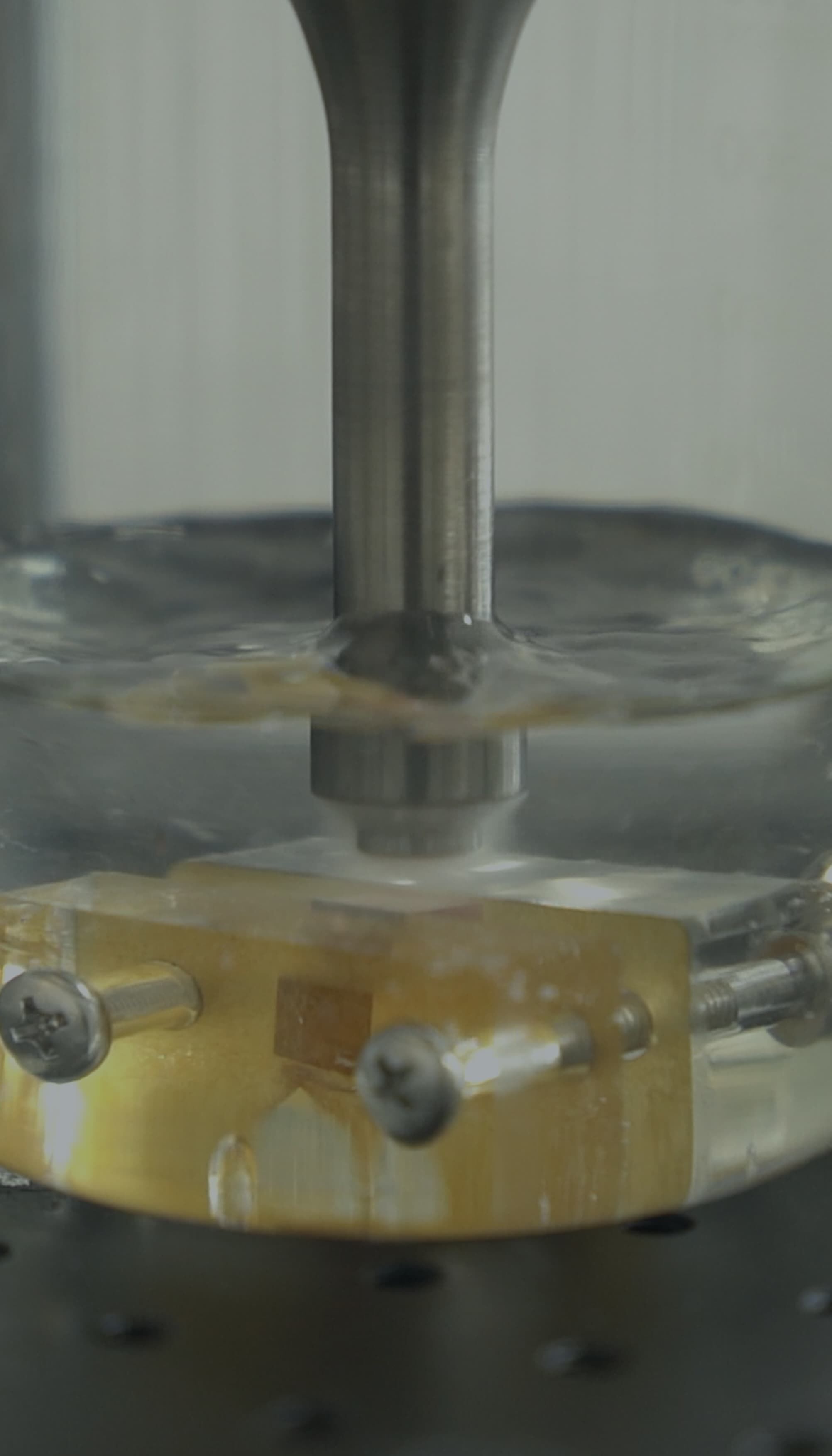

When the stiffness of the bolt is low compared to the piezoelectric ceramic, the electromechanical coupling k2 will be maximized, allowing the piezoelectric ceramic to expand relatively freely without being hindered by the bolt. By using long bolts and reducing...

Yield strength is also called yield limit. The stress at yield is called yield limit, and the unit is MPa. Yield strength is an inherent property of the material, which indicates the critical stress value when the material yields. It is often used to determine the maximum allowable load of mechanical parts.

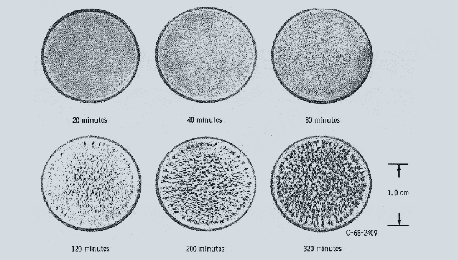

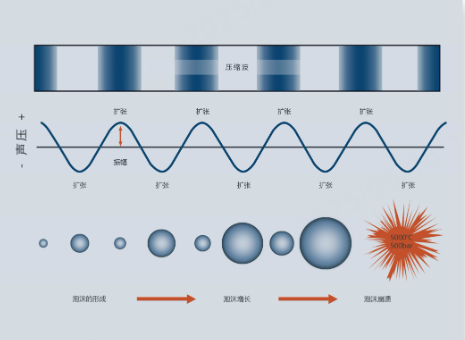

Cavitation erosion occurs when a material is exposed to a cavitating fluid. Collapsing cavitation bubbles induce strong shock waves and microjets, which in turn induce highly localized surface stresses. This repetition of loads due to repeated bubble collapse can lead to localized surface fatigue failure and subsequent shedding or spalling of the material.

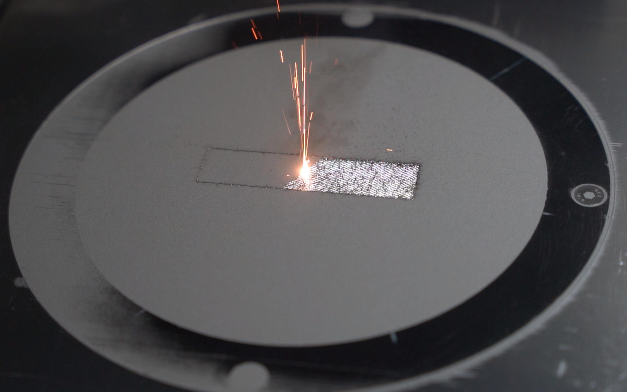

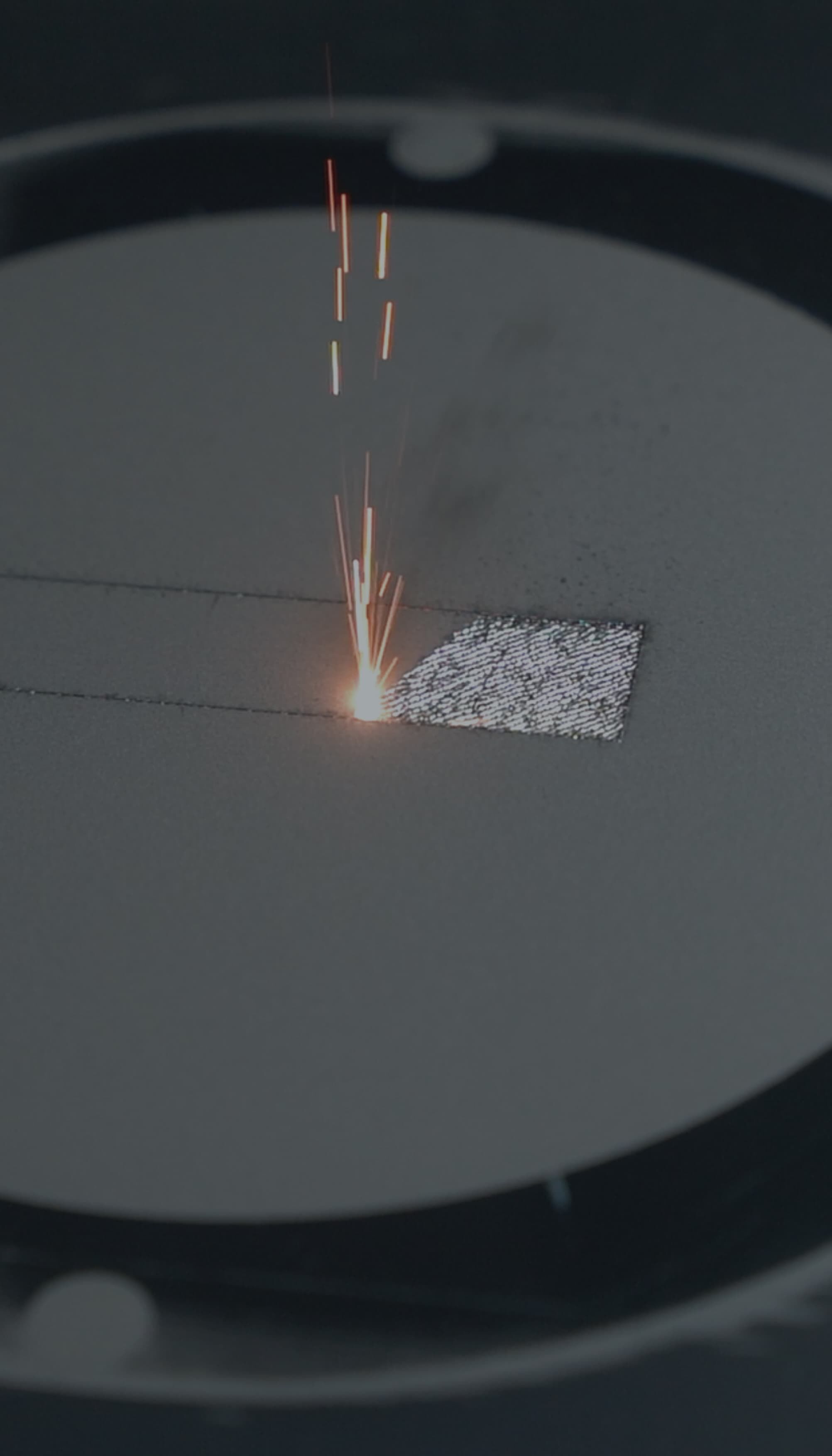

Laser cutting is one of the thermal cutting methods. The principle of laser cutting is to use a focused high-power density laser beam to irradiate the workpiece, causing the irradiated material to quickly melt, vaporize, ablate or reach the ignition point, and at the same time use a high-speed airflow coaxial with the beam to blow away the molten material, thereby achieving cutting of the workpiece.

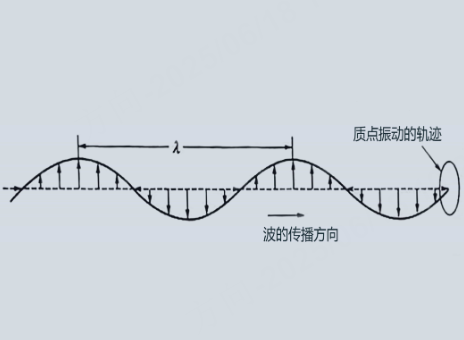

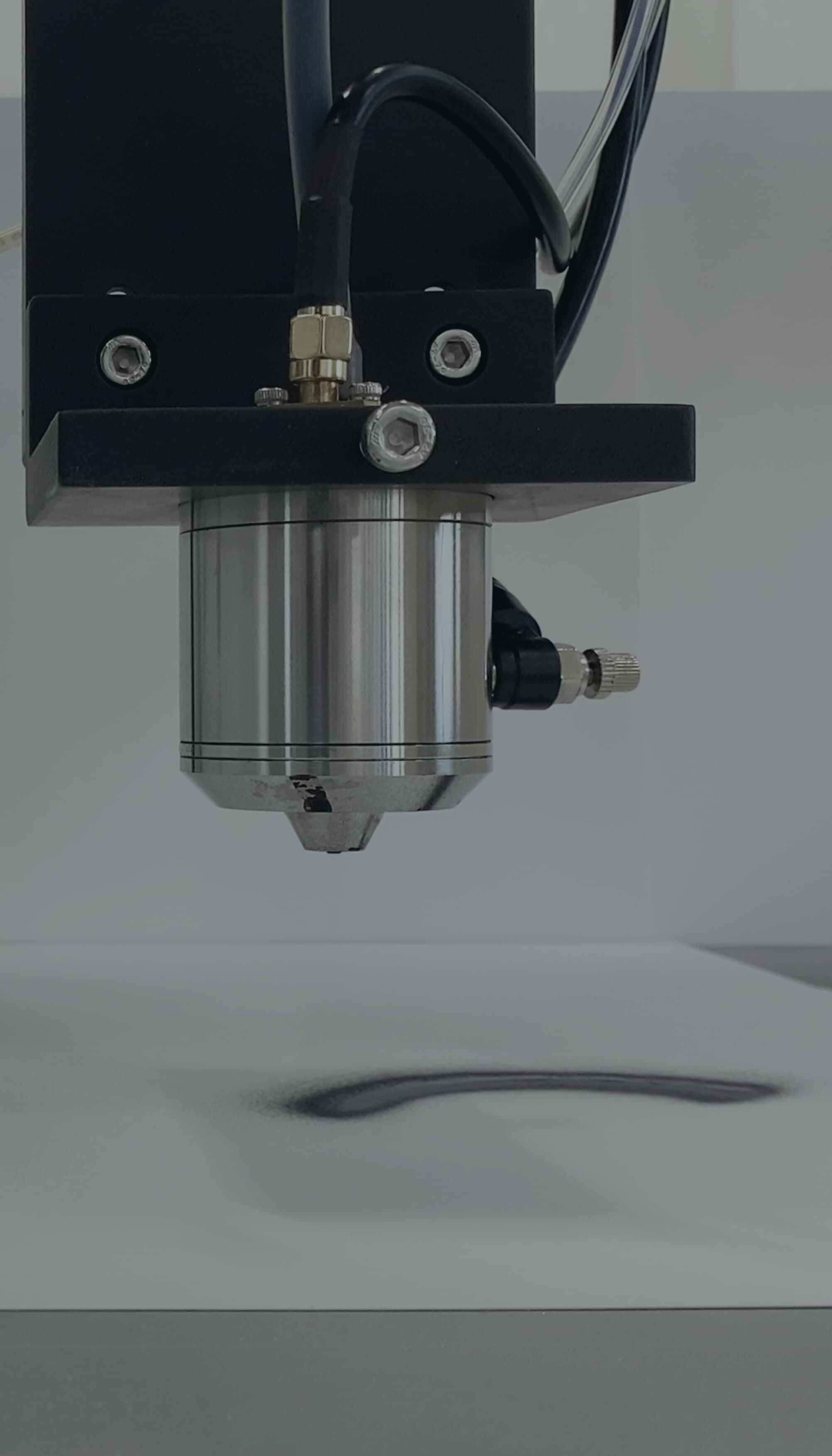

Ultrasonic waves refer to ultra-high frequency sound waves with frequencies exceeding the normal range of human hearing. It is a mechanical wave with an extremely short wavelength, which is generally shorter than 2 cm in the air. It must rely on a medium to propagate and cannot exist in a vacuum (such as space). It propagates farther in water than in air, but because of its short wavelength, it is very easy to lose and scatter in the air, and is not as far-reaching as audible sound and infrasound.

Ultrasonic mechanical effect refers to the general term for various mechanical effects produced by the interaction between ultrasonic waves and the medium when they propagate in the medium. Specifically, when ultrasonic waves propagate in the medium, they will cause the particles in the medium to vibrate, and this vibration will produce mechanical effects such as displacement, deformation, acceleration, etc.

WELCOME TO CONTACT US FOR YOUR CUSTOMIZED SOLUTION

Production Experience

Annual Production Capacity

Company Staff

Dust-free Workshop

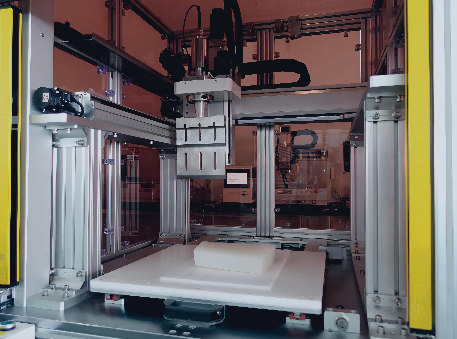

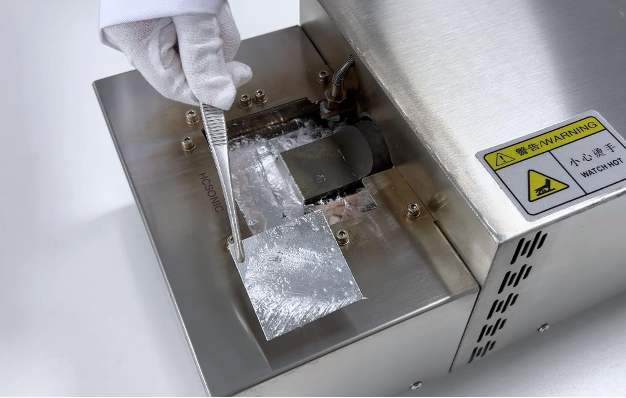

The company adheres to the path of independent research and development and innovation, and has many technical experts in the field of materials and multiple intellectual property rights in additive manufacturing. It has cooperated with top domestic universities and research institutions to overcome a number of internationally leading technologies, and launched advanced ultrasonic manufacturing metal powder products both at home and abroad. The metal powder products produced by our company are involved in aerospace, medical devices, automotive sectors, etc. The metal powder products produced by the company include 3D printing metal powder, solder powder, pure indium powder, indium-based alloy powder, bismuth powder, etc. We provide customers with advanced and reliable metal powder materials. We offer both finished metal powder sales and metal powder processing services.